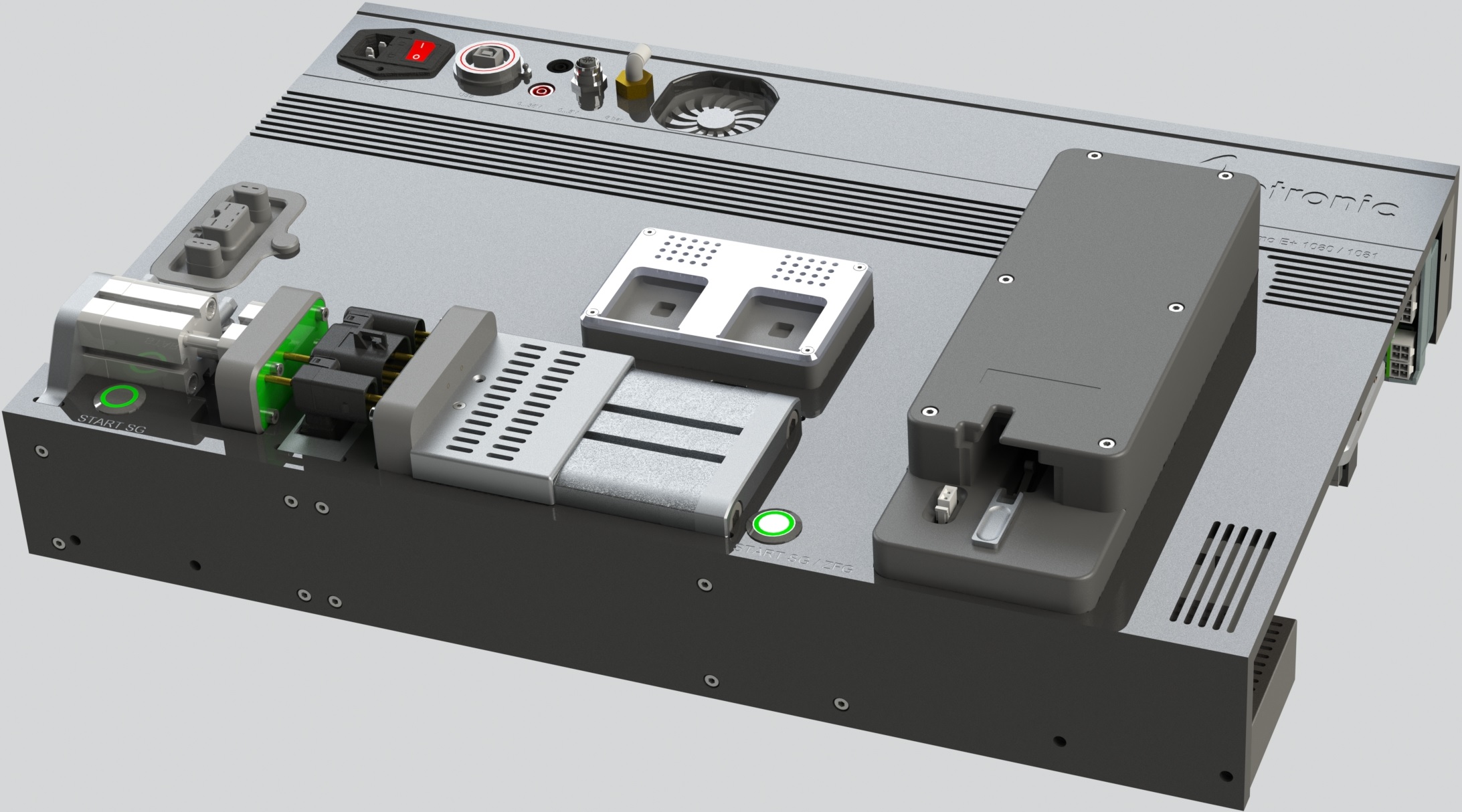

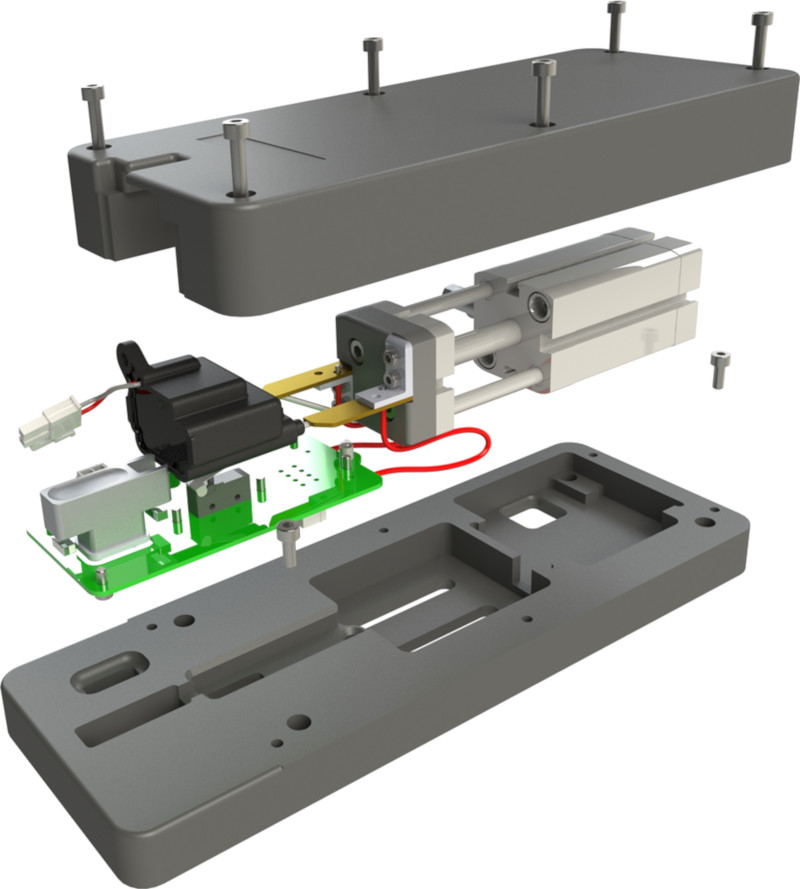

Exploded diagram of a test chamber for an ignition spark generator

The vast majority of the testing devices are semi-automated, meaning that contacting by pneumatic cylinders, for example, happens automatically. As shown in this exploded diagram, the design appears simple on the outside but is actually significantly more complex. To protect the user and the test specimen, safety mechanisms are always integrated. For example, actuated microswitches have to send a release signal before a powerful pneumatic signal is activated or the ignition spark is generated.

An important feature of our testing devices is their robustness. For just under 15 years, some of them have been used every week without showing signs of mechanical wear.

|

|

Deutsch

Deutsch