|

|

Rotary selector for air heating

For a new air heating device, we have the opportunity to design, develop, and mass-produce a rotary selector. The rotary selector will allow the heating system to be turned on and off, set the temperature, and visualize error states. During the concept phase, we were able to present various design concepts, from which our client selected a favorite. We are now transitioning this concept into series production. Extensive validation tests are being conducted to ensure long-lasting and safe operation.

|

|  |

|

Storage extension

The detailed planning for our urgently needed storage extension is complete. We have therefore reached an important milestone. Our goal is to finish the shell construction by the end of the year.

|

|

|  |

|

|

System diagnostics

By delegation of an automotive supplier, we are developing a diagnostic adapter for heaters. Specially designed for the harsh environmental conditions in workshops, this is needed to read out the error memory and test individual components.

|

|  |

|

Redesign and production site relocation

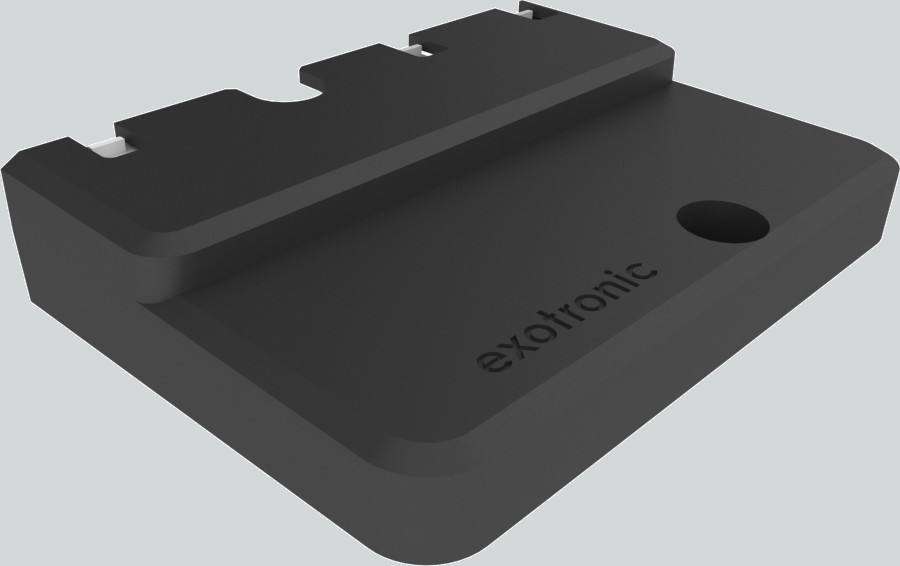

Component discontinuations are sometimes part of the life cycle of an electronic product. We are currently working on such a component substitution for a ECU of a heating system. At the same time, the production facility is to be relocated to us. For this purpose, essential adjustments have to be made and all auxiliary tools have to be redesigned and manufactured.

|

|

|  |

|

|

Control unit for roof hatch DHC 2

In 2009 our first own roof hatch control called “DHC” was released. The abbreviation stands for "Digital Hatch Control" and describes the digital functionality based on the LIN-S-Bus communication.

After almost 14 years, a redesign is necessary to ensure long-term component availability. On the other hand, production-side optimizations such as replacing the two-piece housing with a one-piece solution should be made possible, with 100 percent backwards compatibility being guaranteed.

|

|  |

|

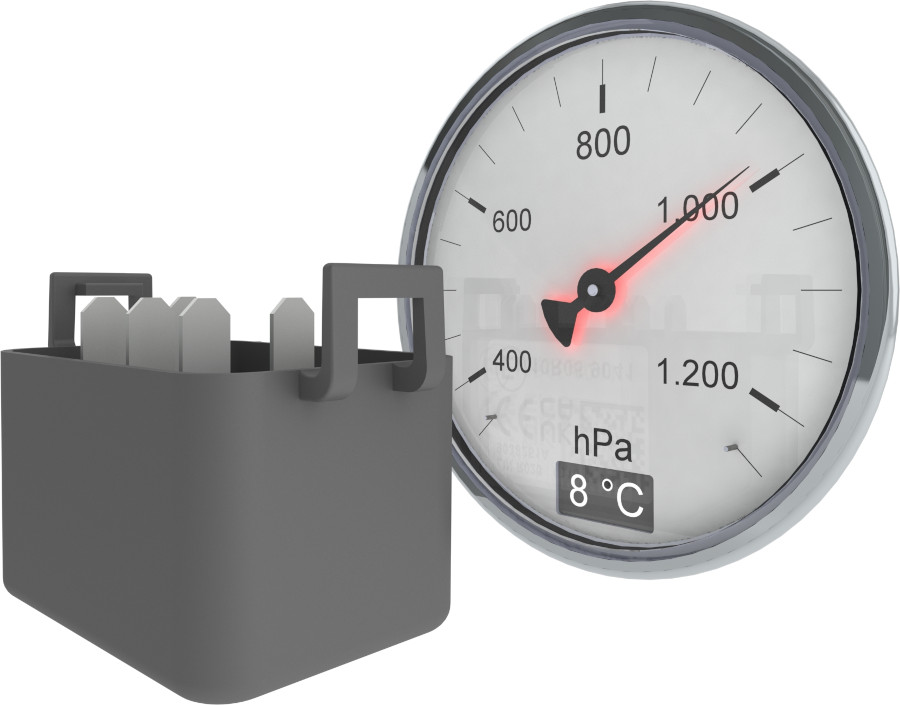

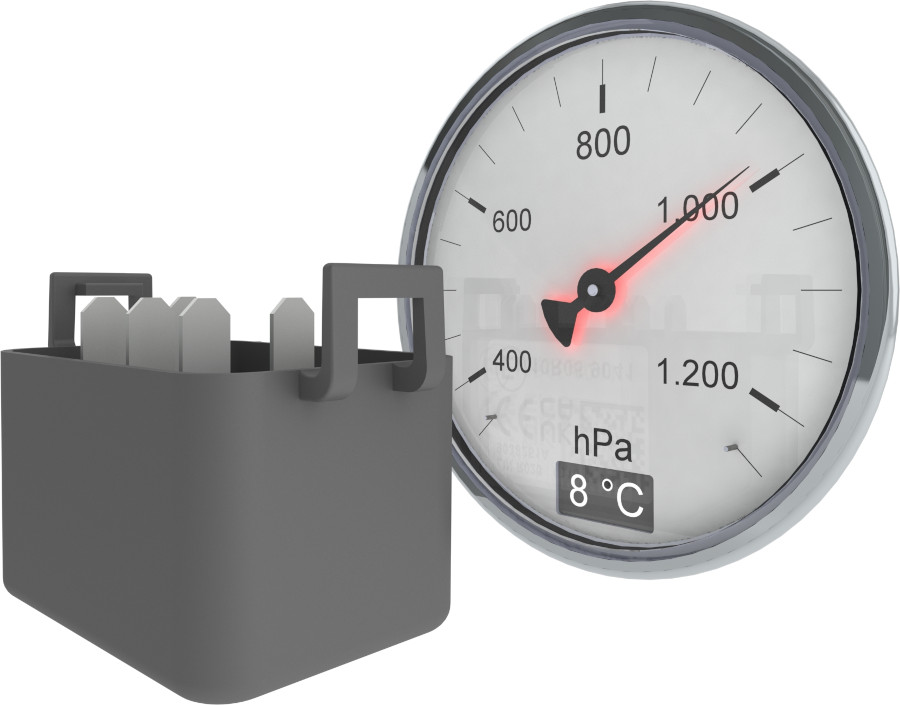

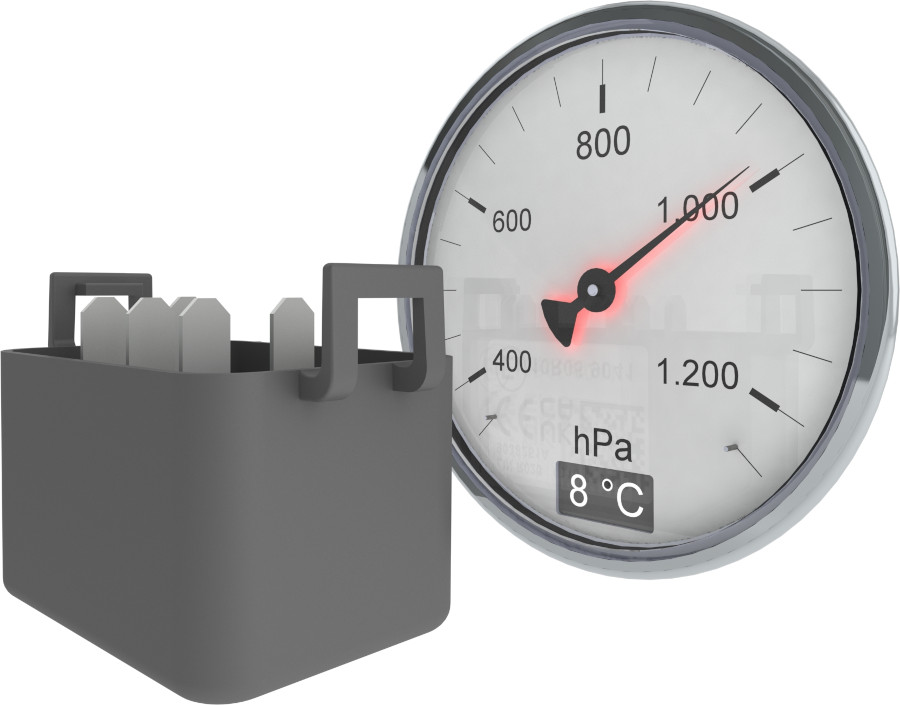

Add-on module for altitude compensation and temperature regulation

In the case of fuel-burning heaters, the ambient pressure plays an important role for optimal combustion and low pollutant emissions. As the pressure increases, the oxygen content decreases. With our new add-on module, this can be influenced and the combustion air supply can be increased. In addition, it offers the possibility to measure the ambient temperature.

|

|

|  |

|

|

Interim ECU replacement for HV heater

The currently tense delivery situation for electronic components requires creative ideas and a high degree of flexibility. As a temporary solution, we were faced with the task of modifying a standard roof hatch ECU within a few weeks so that it could be used as a high-voltage ECU. In addition to minor hardware changes, this required extensive software adjustments. The successfully completed validation paved the way for series use.

|

|  |

|

New "ThermoControl" control panel

Small, powerful, inexpensive and universal - - these attributes are embodied in our new control panel concept called "ThermoControl". Equipped with 8 touch sensors and a display, it can be used for a wide range of applications, such as an air conditioning control panel, pre-selection timer for heaters, roof hatch operation or light control. Both CAN and LIN bus communication are supported. these attributes are embodied in our new control panel concept called "ThermoControl". Equipped with 8 touch sensors and a display, it can be used for a wide range of applications, such as an air conditioning control panel, pre-selection timer for heaters, roof hatch operation or light control. Both CAN and LIN bus communication are supported.

Our goal is to offer different assembly variants in order to be able to offer the required technical parameters at optimized costs.

|

|

|  |

|

|

Building project – extension

Based on the increasing number of serial products and the steadily increasing importance of component availability, we will reach the limits of our storage capacity in the future. To counteract this situation early on, we have planned a new building extension that, in addition to increasing storage capacity by 80%, will also create additional development workstations. In addition, mechanical production will move to a room specially designed for the purpose in order to make production more efficient. Construction is scheduled to begin in 2022.

|

|  |

|

Conversion to serial production of heater control unit

A control unit, produced by another company for years, had to be converted for our production facility as quickly as possible. In addition to making adjustments to auxiliary devices for our machines, we also had the challenge of redeveloping an end-of-line testing device that was getting on in years. We mastered this conversion process, atypical for us, and have been producing a premium control unit for vehicle heaters at our company since December 2021.

|

|

|  |

|

|

Air conditioning control panel for OEM

We had the honour of developing an air conditioning control panel for a bus manufacturer. With this project, the focus was, for the first time, on the mechanics instead of the electronics. As these are visible plastic parts, completely different requirements apply. Sink marks must be avoided, the gaps between the buttons must be uniform, and the haptics must not result in a negative impression. With a customised full-graphic display, 11 buttons and two control knobs the result is a highly intuitive, classic and high-quality control panel. We are proud of the result.

|

|

|

|

Copyright © 2025 Exotronic GmbH. All rights reserved.

info@exotronic.de | +49 (0) 39605 279 0 | Schwarzer Weg 2 | 17094 Groß Nemerow | Germany

Data protection

Imprint

|

|

Rotary selector for air heating

For a new air heating device, we have the opportunity to design, develop, and mass-produce a rotary selector. The rotary selector will allow the heating system to be turned on and off, set the temperature, and visualize error states. During the concept phase, we were able to present various design concepts, from which our client selected a favorite. We are now transitioning this concept into series production. Extensive validation tests are being conducted to ensure long-lasting and safe operation.

|

Storage extension

The detailed planning for our urgently needed storage extension is complete. We have therefore reached an important milestone. Our goal is to finish the shell construction by the end of the year.

|

|

System diagnostics

By delegation of an automotive supplier, we are developing a diagnostic adapter for heaters. Specially designed for the harsh environmental conditions in workshops, this is needed to read out the error memory and test individual components.

|

Redesign and production site relocation

Component discontinuations are sometimes part of the life cycle of an electronic product. We are currently working on such a component substitution for a ECU of a heating system. At the same time, the production facility is to be relocated to us. For this purpose, essential adjustments have to be made and all auxiliary tools have to be redesigned and manufactured.

|

|

Control unit for roof hatch

In 2009 our first own roof hatch control called “DHC” was released. The abbreviation stands for "Digital Hatch Control" and describes the digital functionality based on the LIN-S-Bus communication.

After almost 14 years, a redesign is necessary to ensure long-term component availability. On the other hand, production-side optimizations such as replacing the two-piece housing with a one-piece solution should be made possible, with 100 percent backwards compatibility being guaranteed.

|

Add-on module for altitude compensation and temperature regulation

In the case of fuel-burning heaters, the ambient pressure plays an important role for optimal combustion and low pollutant emissions. As the pressure increases, the oxygen content decreases. With our new add-on module, this can be influenced and the combustion air supply can be increased. In addition, it offers the possibility to measure the ambient temperature.

|

|

Interim ECU replacement for HV heater

The currently tense delivery situation for electronic components requires creative ideas and a high degree of flexibility. As a temporary solution, we were faced with the task of modifying a standard roof hatch ECU within a few weeks so that it could be used as a high-voltage ECU. In addition to minor hardware changes, this required extensive software adjustments. The successfully completed validation paved the way for series use.

|

New "ThermoControl" control panel

Small, powerful, inexpensive and universal - - these attributes are embodied in our new control panel concept called "ThermoControl". Equipped with 8 touch sensors and a display, it can be used for a wide range of applications, such as an air conditioning control panel, pre-selection timer for heaters, roof hatch operation or light control. Both CAN and LIN bus communication are supported. these attributes are embodied in our new control panel concept called "ThermoControl". Equipped with 8 touch sensors and a display, it can be used for a wide range of applications, such as an air conditioning control panel, pre-selection timer for heaters, roof hatch operation or light control. Both CAN and LIN bus communication are supported.

Our goal is to offer different assembly variants in order to be able to offer the required technical parameters at optimized costs.

|

|

Building project – extension

Based on the increasing number of serial products and the steadily increasing importance of component availability, we will reach the limits of our storage capacity in the future. To counteract this situation early on, we have planned a new building extension that, in addition to increasing storage capacity by 80%, will also create additional development workstations. In addition, mechanical production will move to a room specially designed for the purpose in order to make production more efficient. Construction is scheduled to begin in 2022.

|

Conversion to serial production of heater control unit

A control unit, produced by another company for years, had to be converted for our production facility as quickly as possible. In addition to making adjustments to auxiliary devices for our machines, we also had the challenge of redeveloping an end-of-line testing device that was getting on in years. We mastered this conversion process, atypical for us, and have been producing a premium control unit for vehicle heaters at our company since December 2021.

|

|

Air conditioning control panel for OEM

We had the honour of developing an air conditioning control panel for a bus manufacturer. With this project, the focus was, for the first time, on the mechanics instead of the electronics. As these are visible plastic parts, completely different requirements apply. Sink marks must be avoided, the gaps between the buttons must be uniform, and the haptics must not result in a negative impression. With a customised full-graphic display, 11 buttons and two control knobs the result is a highly intuitive, classic and high-quality control panel. We are proud of the result.

|

|

Copyright © 2025 Exotronic GmbH. All rights reserved.

info@exotronic.de | +49 (0) 39605 279 0 | Schwarzer Weg 2 | 17094 Groß Nemerow | Germany

Data protection

Imprint

|

Deutsch

Deutsch