|

Icy temperatures of |  |

| ||

|

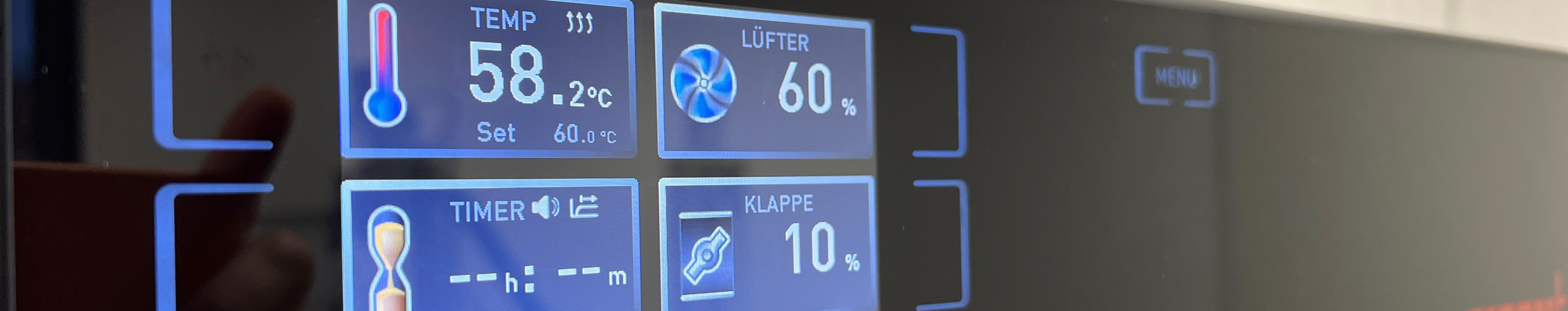

Environmental simulation

The properties and functionality of electronic components are influenced by thermal and climatic conditions during transportation, storage and operation. Temperature and climate tests, which are required as early as the development phase and in various approval tests, ensure and optimise product quality. Exotronic GmbH has a climatic exposure test cabinet and a heat cabinet for this purpose.

|  |

| ||

|

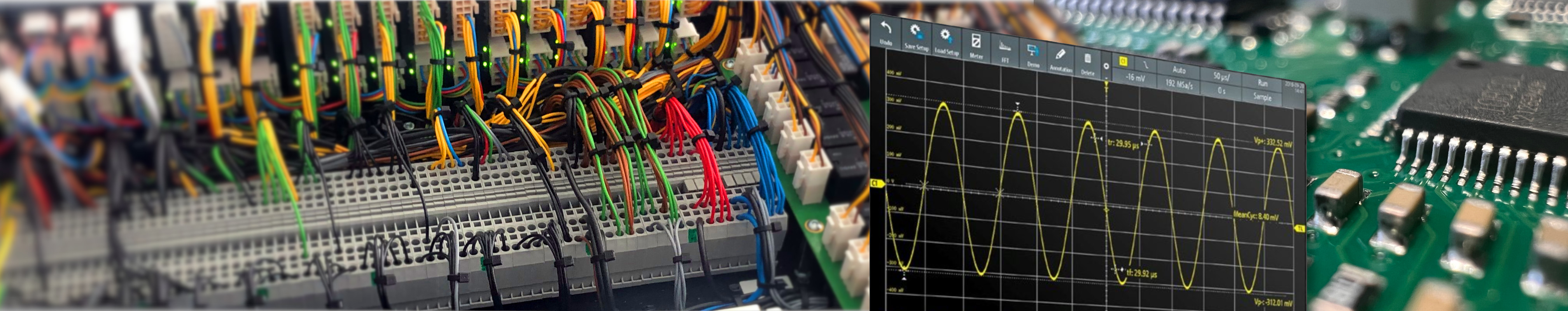

Electrical tests

Electrical tests are an important part of every development process. As early as the A Model phase, comprehensive tests are carried out to ensure the product’s suitability under all specified conditions. Most of these tests are carried out internally. |  |

| ||

|

100 % testing

In order to meet our quality standards, each of our serial products is tested before delivery to the customer. A customer-specific end-of-line testing device that automatically tests and documents nearly every function is developed and produced specifically for this. This way we can ensure that only 100% tested and faultless products leave the premises. | |

|

Copyright © 2025 Exotronic GmbH. All rights reserved. | ||

|

Environmental simulation

The properties and functionality of electronic components are influenced by thermal and climatic conditions during transportation, storage and operation. Temperature and climate tests, which are required as early as the development phase and in various approval tests, ensure and optimise product quality. Exotronic GmbH has a climatic exposure test cabinet and a heat cabinet for this purpose.

| ||

Electrical tests

Electrical tests are an important part of every development process. As early as the A Model phase, comprehensive tests are carried out to ensure the product’s suitability under all specified conditions. Most of these tests are carried out internally. | ||

|

100 % testing

In order to meet our quality standards, each of our serial products is tested before delivery to the customer. A customer-specific end-of-line testing device that automatically tests and documents nearly every function is developed and produced specifically for this. This way we can ensure that only 100% tested and faultless products leave the premises. | ||

|

Copyright © 2025 Exotronic GmbH. All rights reserved. | ||

Deutsch

Deutsch