|

|

Range of services

Product design

Designing picture masks

CAD visualisation of draft designs

Creating photo-realistic illustrations (rendering)

Providing advice on production processes and material selection

Commissioning prototypes in rapid prototyping

Guidance through to serial production possible

|

|  |

|

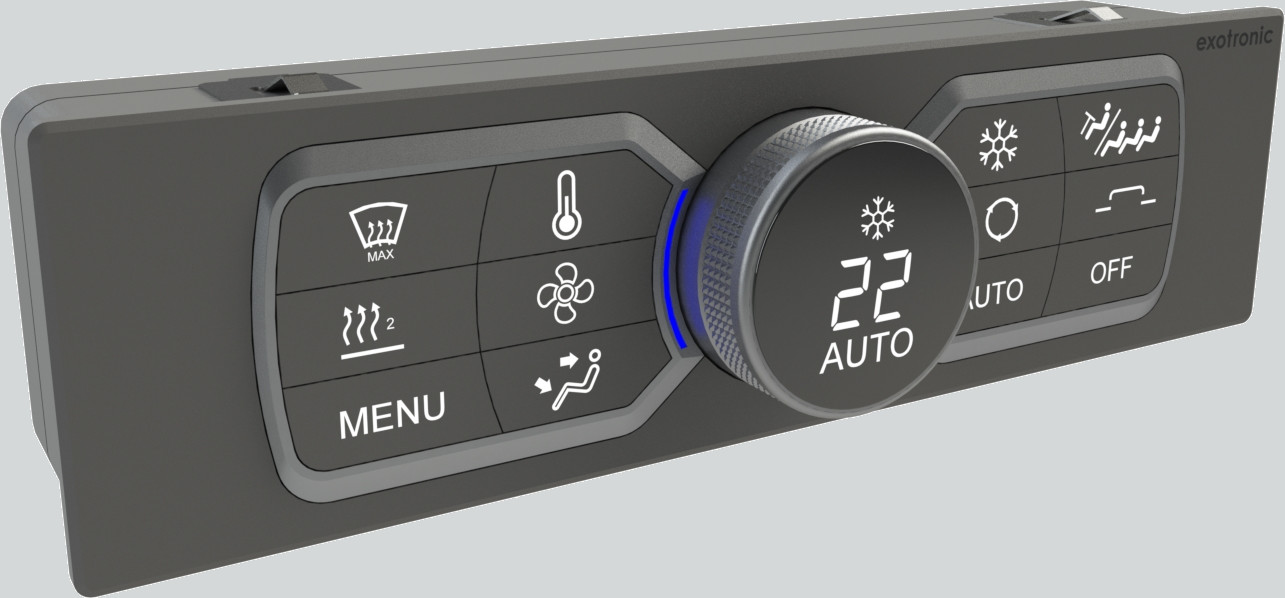

New "ThermoControl" control panel

Small, powerful, inexpensive and universal - - these attributes are embodied in our new control panel concept called "ThermoControl". Equipped with 8 touch sensors and a display, it can be used for a wide range of applications, such as an air conditioning control panel, pre-selection timer for heaters, roof hatch operation or light control. Both CAN and LIN bus communication are supported. these attributes are embodied in our new control panel concept called "ThermoControl". Equipped with 8 touch sensors and a display, it can be used for a wide range of applications, such as an air conditioning control panel, pre-selection timer for heaters, roof hatch operation or light control. Both CAN and LIN bus communication are supported.

Our goal is to offer different assembly variants in order to be able to offer the required technical parameters at optimized costs.

|

|

|  |

|

|

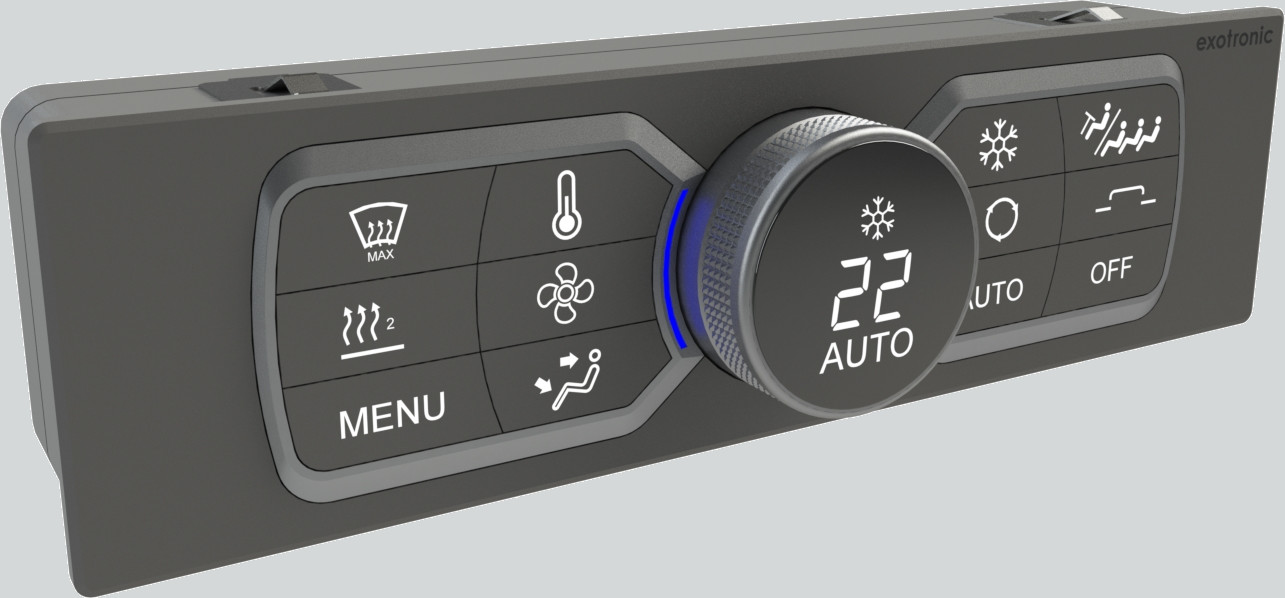

Study: central control panel for air conditioning functions and more

Operating most of the functions with one central control panel was the starting point of this study. A rotary knob with just 4 other buttons within reach of the driver is our solution. The user will be assisted by additional displays, cost-effectively solved through backlit symbols that provide information about the menu currently active.

An appealing night design with an elaborately illuminated ring on the rotary knob, along with high-quality matt aluminium surface applications, complete this control panel.

|

|  |

|

Driver Unit II roof hatch control panel

Our Driver Unit (roof hatch control panel) has been on the market for 1.5 decades and is due for a redesign. Higher visual quality while maintaining an attractive parts price - just one premise of the study.

Black, glass-like surfaces are the current trend in cars and, increasingly, in buses too. Taking this as a starting point, we designed a control panel with a rotary knob via which the roof hatch selection can be made and the roof hatch position can be selected. The current positions of all hatches are displayed with LEDs. And all this in a classy, glass-like black surface.

|

|

|  |

|

|

Roof hatch control panel with integrated control system

A button for a roof hatch, which also has the control system for the motors integrated – – our approach for markets in which price is critically important with just 1...2 roof hatches per bus. our approach for markets in which price is critically important with just 1...2 roof hatches per bus.

The button can be pressed sequentially in order to select the 4 different roof hatch positions. The selected roof hatch position will be displayed on the button itself. The colour of the backlighting can be selected so that the button blends seamlessly into the cockpit.

The prototype is chosen using the dimensions so that it will fit into the recess of a standard switch.

|

|  |

|

|

Design study: air conditioning control panel

How can an air conditioning control panel be designed if cost considerations are disregarded? We asked ourselves this question and designed an HMI that primarily consists of a huge touchscreen and also has two control knobs, which are equipped with integrated colour displays in turn.

The possibilities are completely new. A scale for the control knob that changes depending on the function. Intuitive, aesthetic and ergonomic.

|

|

|  |

|

|

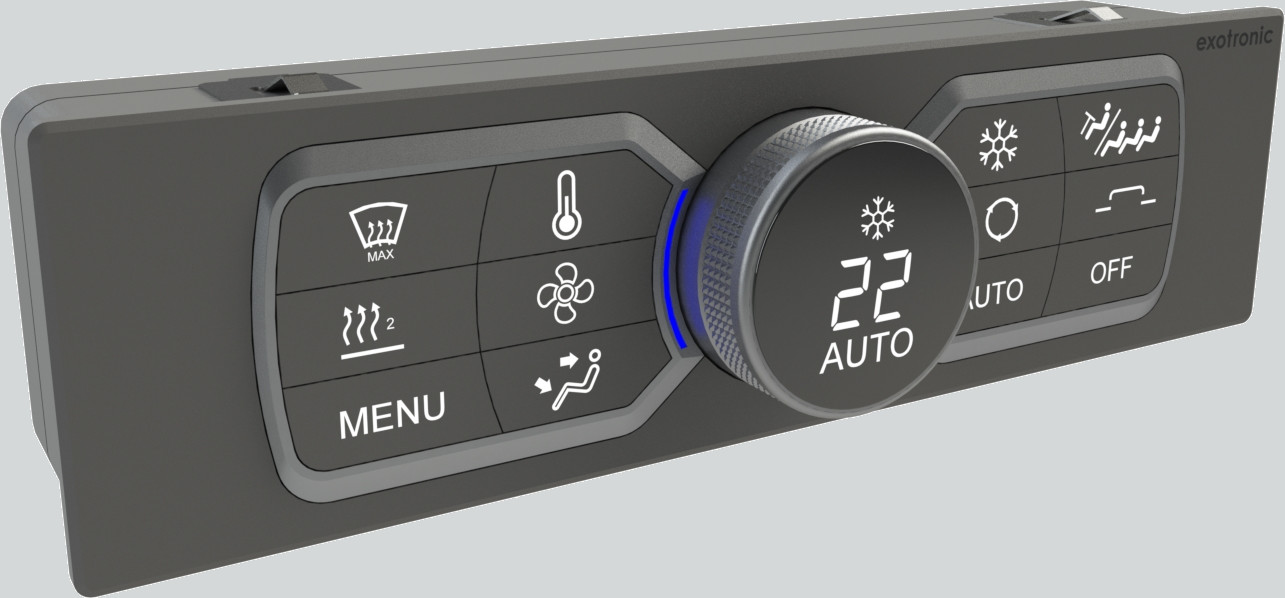

Air conditioning control panel design for bus manufacturer

In 2017, we came up with various designs for an air conditioning control panel (HVAC HMI) for a potential development order for a bus manufacturer. In the design shown here, the monochrome display is arranged within the rotary knob.

|

|  |

|

|

Air conditioning control panel design for bus manufacturer

In 2017, we came up with various designs for an air conditioning control panel (HVAC HMI) for a potential development order for a bus manufacturer.

|

|

|  |

|

|

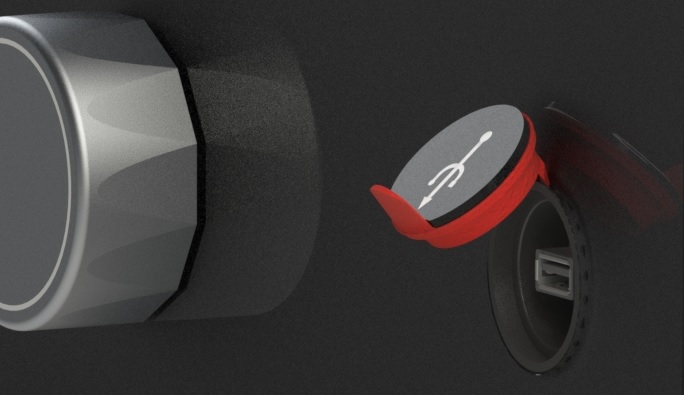

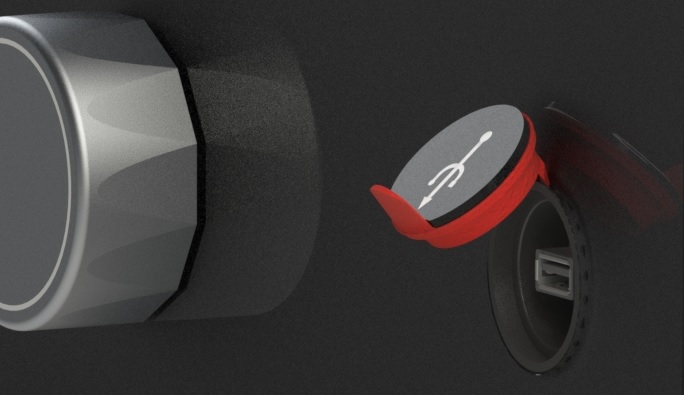

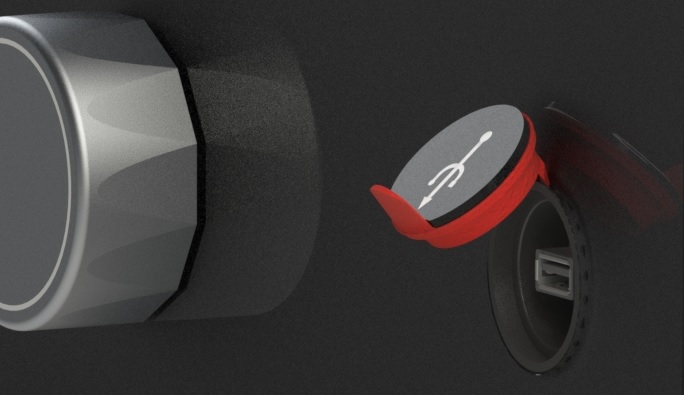

Waterproof USB interface for Eloma combi steamer JOKER

We had to design a waterproof USB interface for the new glass panel of the combi steamer JOKER. We worked on various designs and manufactured the favoured components to be production-ready. Prototype production was also in our hands.

|

|  |

|

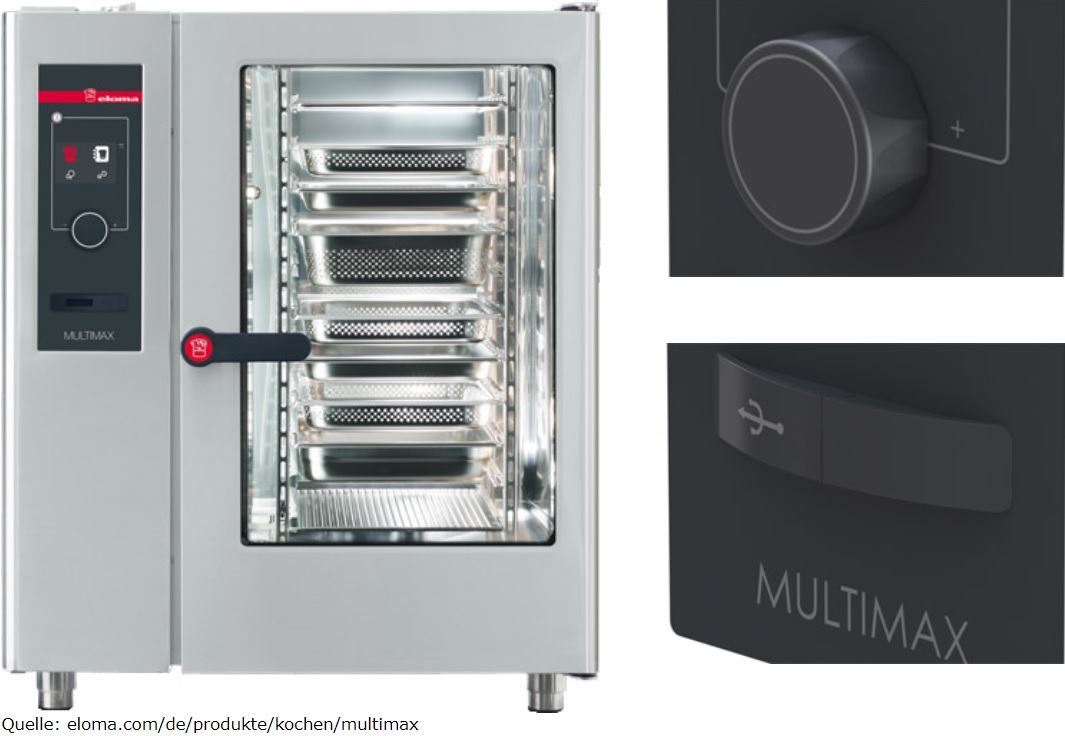

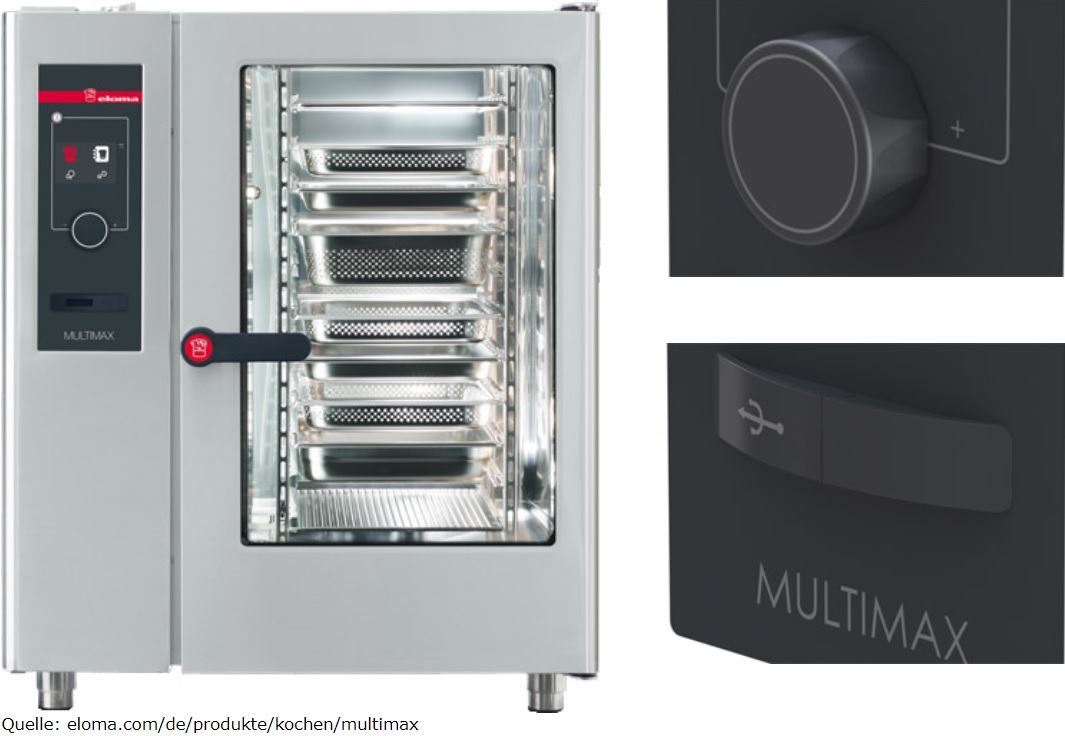

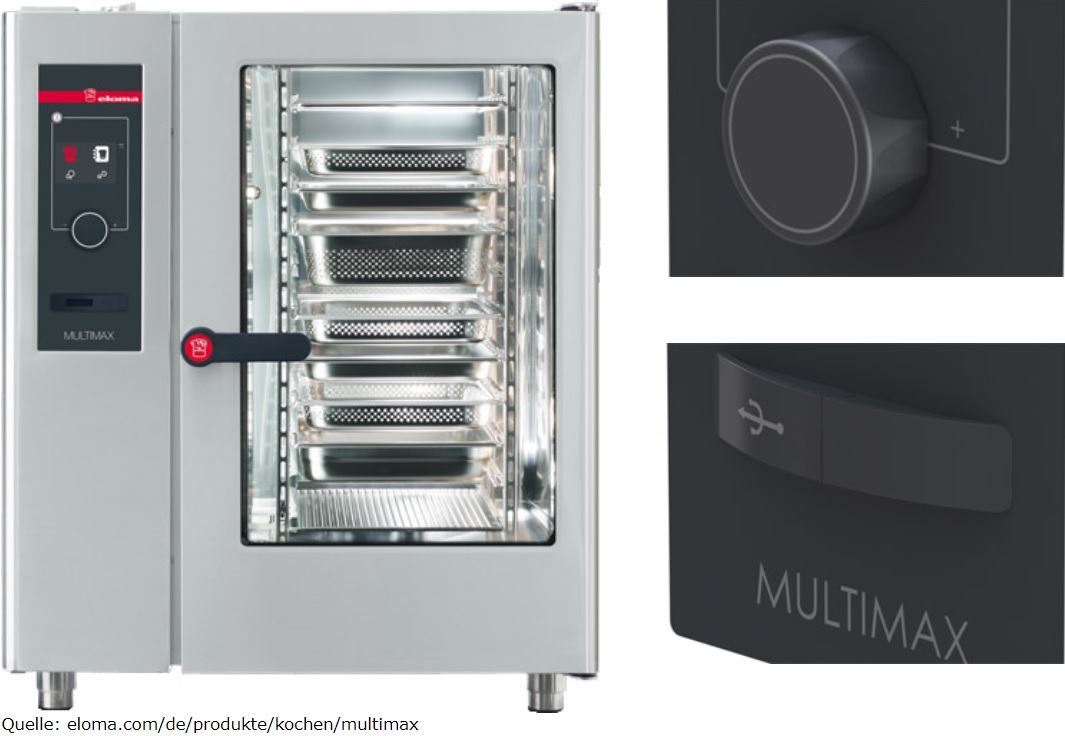

Designing the Eloma Multimax control panel

We were responsible for designing the control panel for the “Multimax” combi steamer from Eloma. The aim of the project was to develop a high-quality human/machine interface whose central control instrument is a control dial/control button. Other important design requirements were that it is easy to clean and grip. We created 27 designs for the control dial alone; Eloma selected its favourite from them. In addition to the control dial, we also developed the front cover and a new interface list.

|

|

|

|

|

Copyright © 2025 Exotronic GmbH. All rights reserved.

info@exotronic.de | +49 (0) 39605 279 0 | Schwarzer Weg 2 | 17094 Groß Nemerow | Germany

Data protection

Imprint

|

|

Range of services

• Product design

• Designing picture masks

• CAD visualisation of draft designs

• Creating photo-realistic illustrations (rendering)

• Providing advice on production processes and material selection

• Commissioning prototypes in rapid prototyping

• Guidance through to serial production possible

|

|

New "ThermoControl" control panel

Small, powerful, inexpensive and universal - - these attributes are embodied in our new control panel concept called "ThermoControl". Equipped with 8 touch sensors and a display, it can be used for a wide range of applications, such as an air conditioning control panel, pre-selection timer for heaters, roof hatch operation or light control. Both CAN and LIN bus communication are supported. these attributes are embodied in our new control panel concept called "ThermoControl". Equipped with 8 touch sensors and a display, it can be used for a wide range of applications, such as an air conditioning control panel, pre-selection timer for heaters, roof hatch operation or light control. Both CAN and LIN bus communication are supported.

Our goal is to offer different assembly variants in order to be able to offer the required technical parameters at optimized costs.

|

|

Study: central control panel for air conditioning functions and more

Operating most of the functions with one central control panel was the starting point of this study. A rotary knob with just 4 other buttons within reach of the driver is our solution. The user will be assisted by additional displays, cost-effectively solved through backlit symbols that provide information about the menu currently active.

An appealing night design with an elaborately illuminated ring on the rotary knob, along with high-quality matt aluminium surface applications, complete this control panel.

|

|

Driver Unit II roof hatch control panel

Our Driver Unit (roof hatch control panel) has been on the market for 1.5 decades and is due for a redesign. Higher visual quality while maintaining an attractive parts price - just one premise of the study.

Black, glass-like surfaces are the current trend in cars and, increasingly, in buses too. Taking this as a starting point, we designed a control panel with a rotary knob via which the roof hatch selection can be made and the roof hatch position can be selected. The current positions of all hatches are displayed with LEDs. And all this in a classy, glass-like black surface.

|

|

Roof hatch control panel with integrated control system

A button for a roof hatch, which also has the control system for the motors integrated – – our approach for markets in which price is critically important with just 1...2 roof hatches per bus. our approach for markets in which price is critically important with just 1...2 roof hatches per bus.

The button can be pressed sequentially in order to select the 4 different roof hatch positions. The selected roof hatch position will be displayed on the button itself. The colour of the backlighting can be selected so that the button blends seamlessly into the cockpit.

The prototype is chosen using the dimensions so that it will fit into the recess of a standard switch.

|

|

Design study: air conditioning control panel

How can an air conditioning control panel be designed if cost considerations are disregarded? We asked ourselves this question and designed an HMI that primarily consists of a huge touchscreen and also has two control knobs, which are equipped with integrated colour displays in turn.

The possibilities are completely new. A scale for the control knob that changes depending on the function. Intuitive, aesthetic and ergonomic.

|

|

Air conditioning control panel design for bus manufacturer

In 2017, we came up with various designs for an air conditioning control panel (HVAC HMI) for a potential development order for a bus manufacturer. In the design shown here, the monochrome display is arranged within the rotary knob.

|

|

Air conditioning control panel design for bus manufacturer

In 2017, we came up with various designs for an air conditioning control panel (HVAC HMI) for a potential development order for a bus manufacturer.

|

|

Wasserdichte USB-Schnittstelle für Eloma Kombidämpfer JOKER

Waterproof USB interface for Eloma combi steamer JOKER

We had to design a waterproof USB interface for the new glass panel of the combi steamer JOKER. We worked on various designs and manufactured the favoured components to be production-ready. Prototype production was also in our hands.

|

|

esigning the Eloma Multimax control panel

We were responsible for designing the control panel for the “Multimax” combi steamer from Eloma. The aim of the project was to develop a high-quality human/machine interface whose central control instrument is a control dial/control button. Other important design requirements were that it is easy to clean and grip. We created 27 designs for the control dial alone; Eloma selected its favourite from them. In addition to the control dial, we also developed the front cover and a new interface list.

|

|

Copyright © 2025 Exotronic GmbH. All rights reserved.

info@exotronic.de | +49 (0) 39605 279 0 | Schwarzer Weg 2 | 17094 Groß Nemerow | Germany

Data protection

Imprint

|

Deutsch

Deutsch