|

|

Plastic

Whether acrylic strip lights, retroactively given a diffuse appearance through glass bead blasting, or a composite material, which is ideal for making control panels, we have a large range of raw materials in stock. We’ll also be happy to provide advice and support during construction.

|

|  |

|

|  |

|

|

Processing extruded profiles

We construct specific clamping devices for processing extruded profiles so that the blanks can be clamped and changed quickly.

The accompanying casing is for a high-voltage control unit. It is fully stripped and processed from three sides. Threads of M3 to M25 are inserted and all the edges are automatically deburred.

|

|  |

|

Aluminium casing

In order to provide industrial measuring technology with sufficient protection against the tough conditions in which they are used, we mill an appropriate case for each application. Plastics are also used so that acrylic light guides can visually signal the function being used.

We can offer you a wide range of options for the surface finish. From simple anodising through to hard coating. We’ll be happy to advise you.

|

|

|  |

|

|

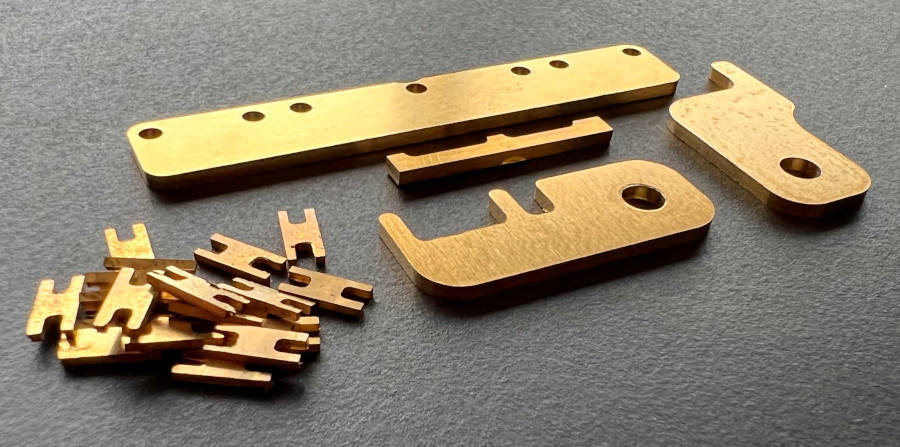

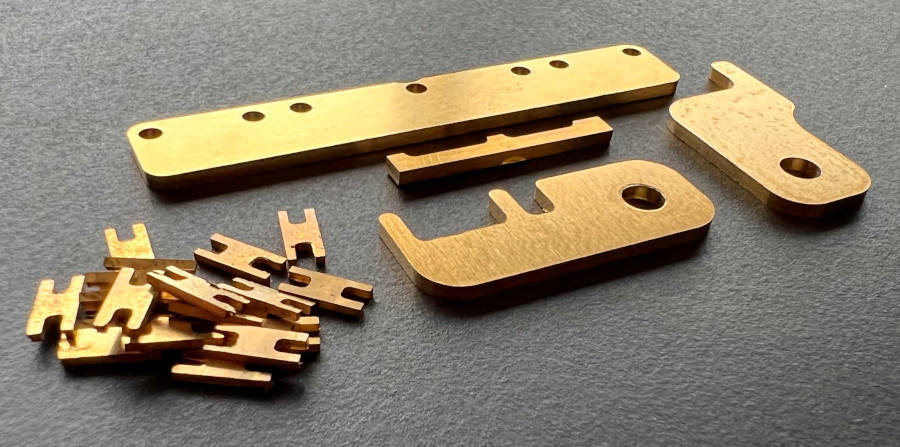

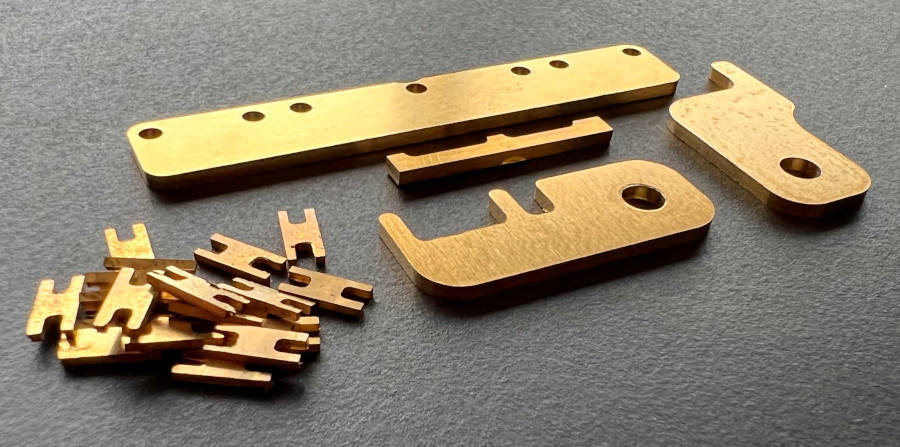

Brass contacts

We’re often faced with the task of manufacturing prototype parts for flat contacts or contact rails before costly and time-consuming die cutting tools can be ordered. The size of the parts is not important here. We can even produce 3-mm elements using special clamping technology.

|

|

|

|

Copyright © 2025 Exotronic GmbH. All rights reserved.

info@exotronic.de | +49 (0) 39605 279 0 | Schwarzer Weg 2 | 17094 Groß Nemerow | Germany

Data protection

Imprint

|

|

Plastic

Whether acrylic strip lights, retroactively given a diffuse appearance through glass bead blasting, or a composite material, which is ideal for making control panels, we have a large range of raw materials in stock. We’ll also be happy to provide advice and support during construction.

|

|

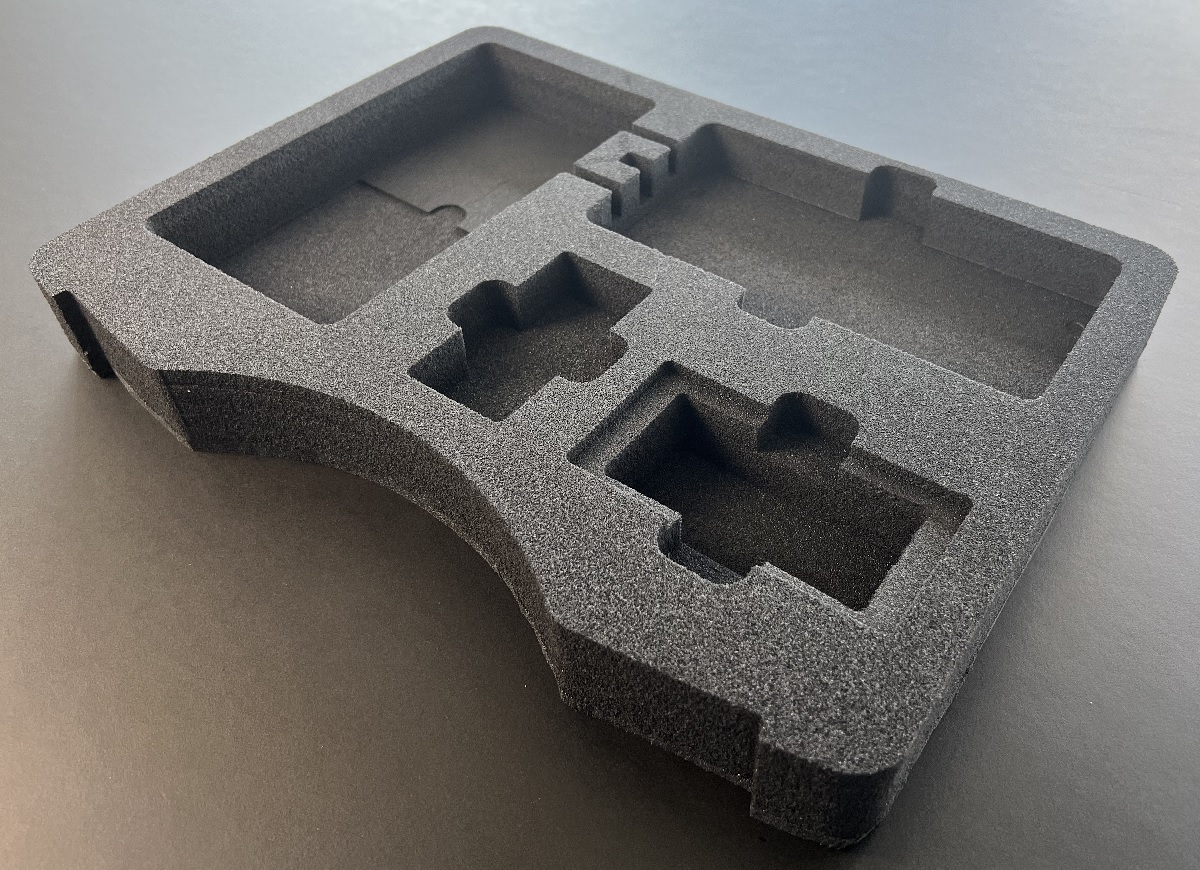

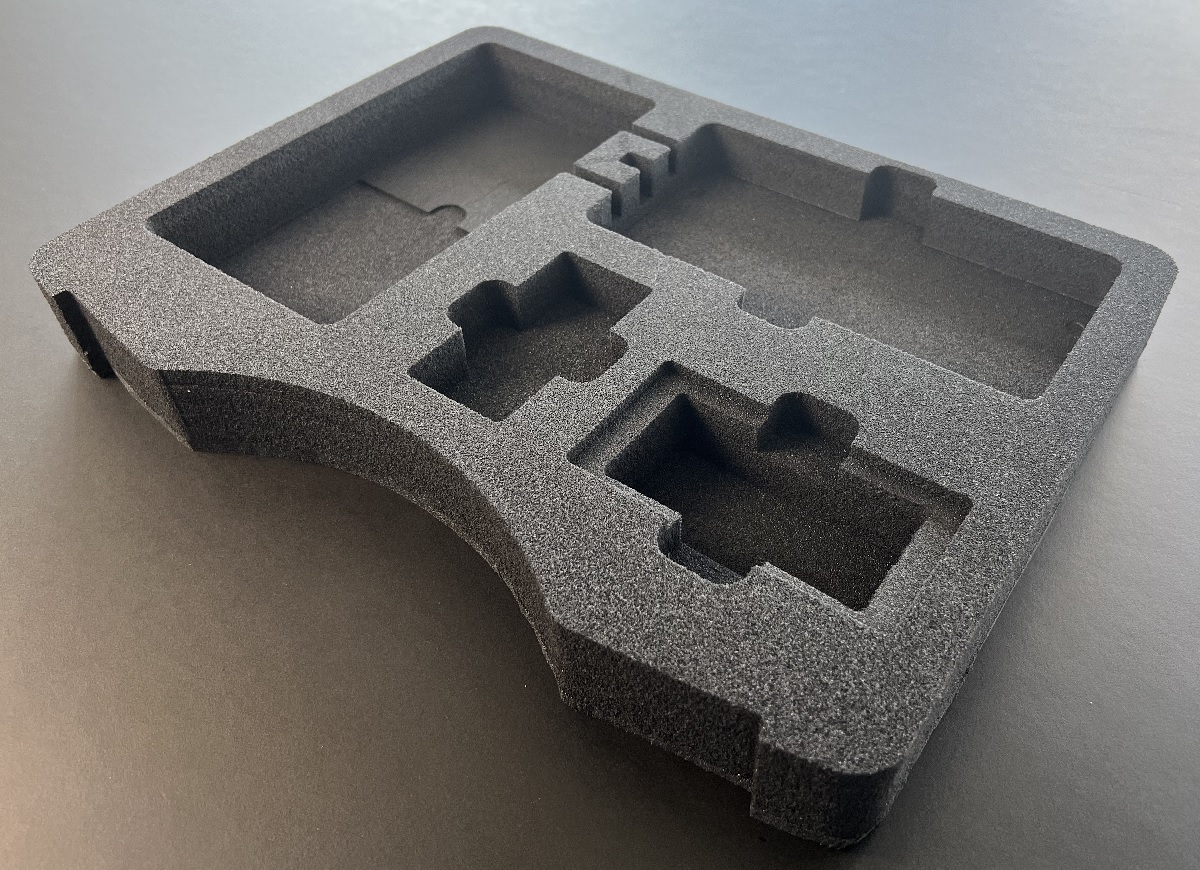

Reusable packaging

In order to reduce packaging costs for larger serial products and thereby generate less packaging waste, we have been using reusable packaging for a few years. For delicate products – – such as control panels for the cockpit such as control panels for the cockpit – – we use foam that is modified by CNC processing so that components are optimally fixed in place and protected. They are nevertheless easy to remove. we use foam that is modified by CNC processing so that components are optimally fixed in place and protected. They are nevertheless easy to remove.

|

|

Processing extruded profiles

We construct specific clamping devices for processing extruded profiles so that the blanks can be clamped and changed quickly.

The accompanying casing is for a high-voltage control unit. It is fully stripped and processed from three sides. Threads of M3 to M25 are inserted and all the edges are automatically deburred.

|

|

Aluminium casing

In order to provide industrial measuring technology with sufficient protection against the tough conditions in which they are used, we mill an appropriate case for each application. Plastics are also used so that acrylic light guides can visually signal the function being used.

We can offer you a wide range of options for the surface finish. From simple anodising through to hard coating. We’ll be happy to advise you.

|

|

Brass contacts

We’re often faced with the task of manufacturing prototype parts for flat contacts or contact rails before costly and time-consuming die cutting tools can be ordered. The size of the parts is not important here. We can even produce 3-mm elements using special clamping technology.

|

|

Copyright © 2025 Exotronic GmbH. All rights reserved.

info@exotronic.de | +49 (0) 39605 279 0 | Schwarzer Weg 2 | 17094 Groß Nemerow | Germany

Data protection

Imprint

|

Deutsch

Deutsch