|

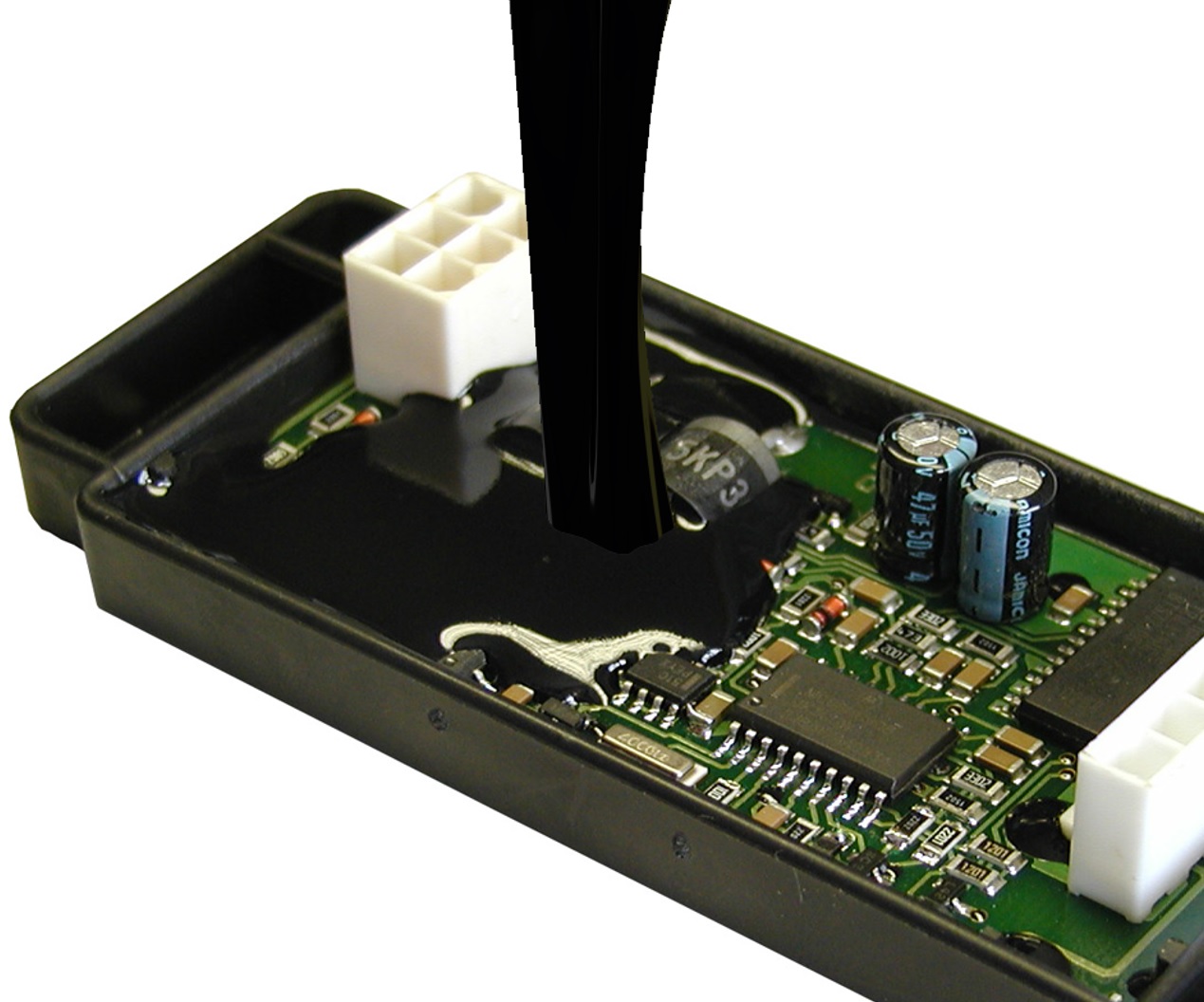

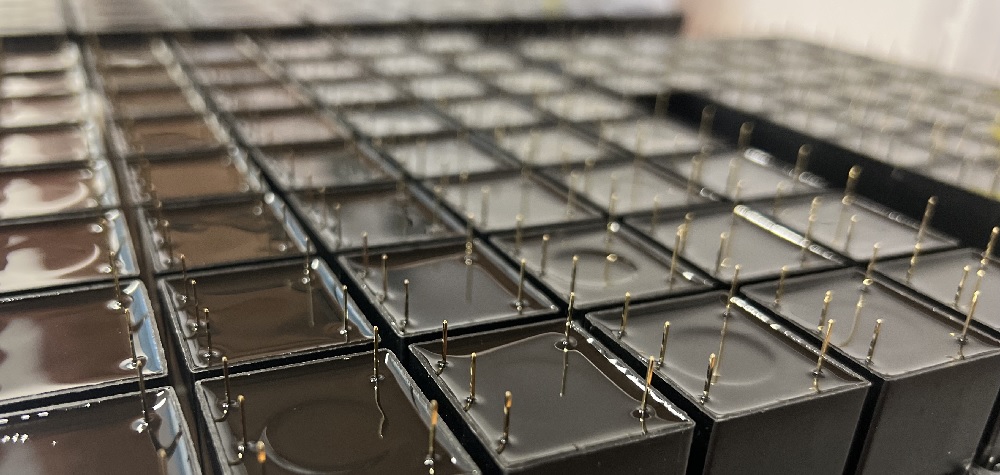

Electronic components are exposed to a number of different environmental conditions that could cause a breakdown or malfunction. This primarily means moisture, which can occur as a result of both condensation and wet conditions. Dirt, soldering flux, gases and acids represent additional risks to functionality. In addition to protective coating, we also offer circuit casting with polyurethane to safely protect circuit boards. The benefits in comparison to protective coating are increased electrical safety, increased mechanical stability due to component fixing, increased dielectric strength, improved heat dissipation and improved protection against the ingress of moisture and dust.

|  |

Deutsch

Deutsch