|

|

Range of services

Constructing detailed components

Visualising existing components

Developing appealing picture masks for graphic interfaces

Creating injection-moulded casing

Creating extruded profiles

Generating bent metal pieces

Deriving technical drawings

Creating photo-realistic images (rendering)

Conversion into all common universal formats

|

|  |

|

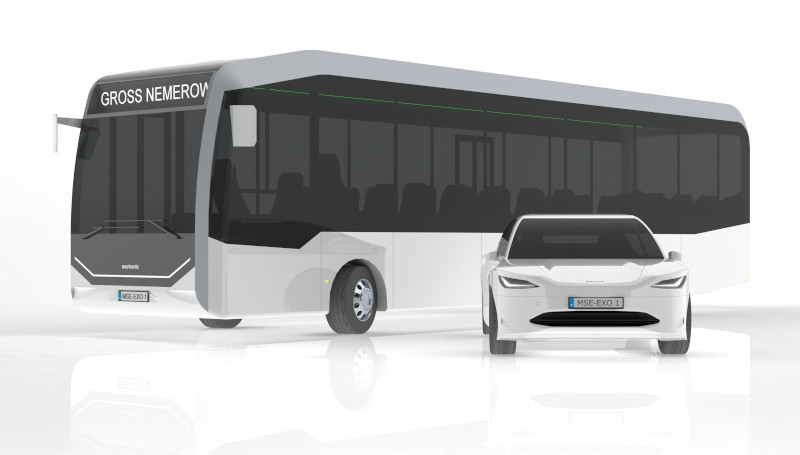

We can do more...

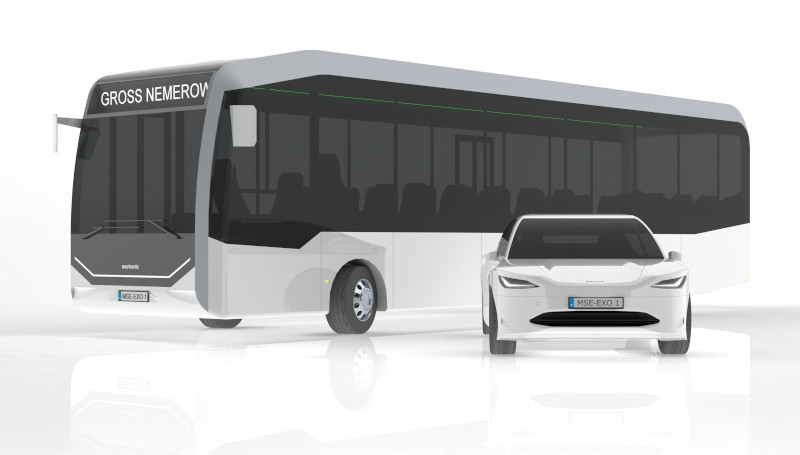

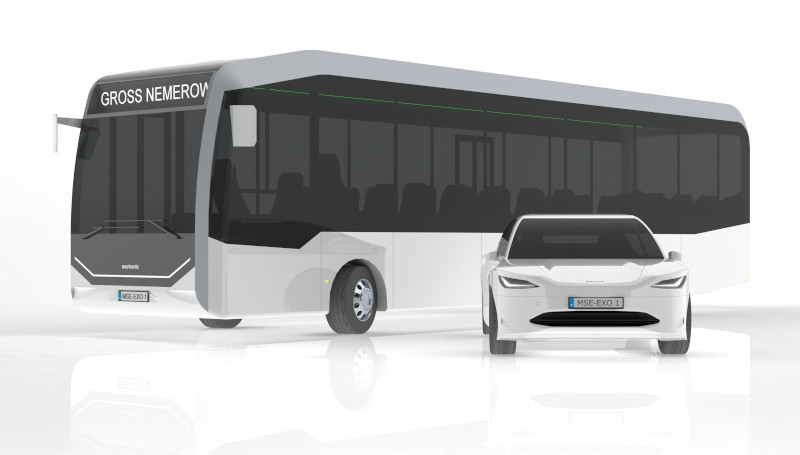

As an example of the fact that we don’t just design electronic components, we have designed a bus and a motor vehicle for the website. The vehicles have their own exterior design, interior, tinted windows and photo-realistic surfaces.

A complex component in CAD but only a small detail on the homepage.

|

|

|  |

|

|

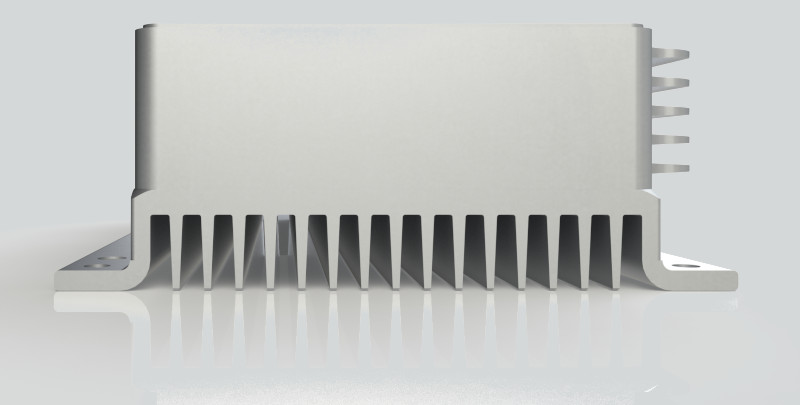

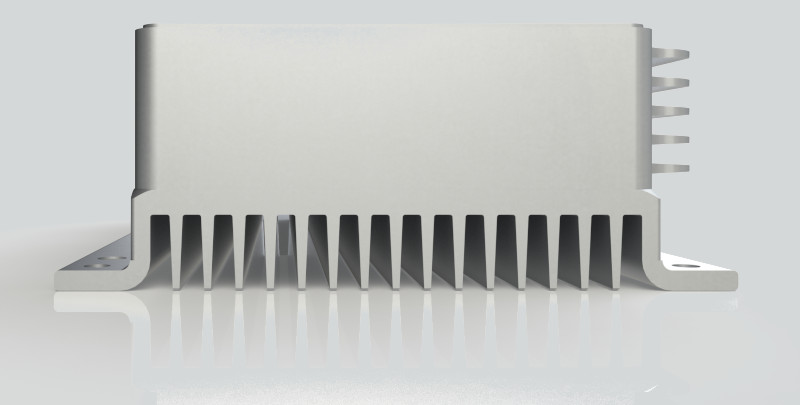

Extruded profiles

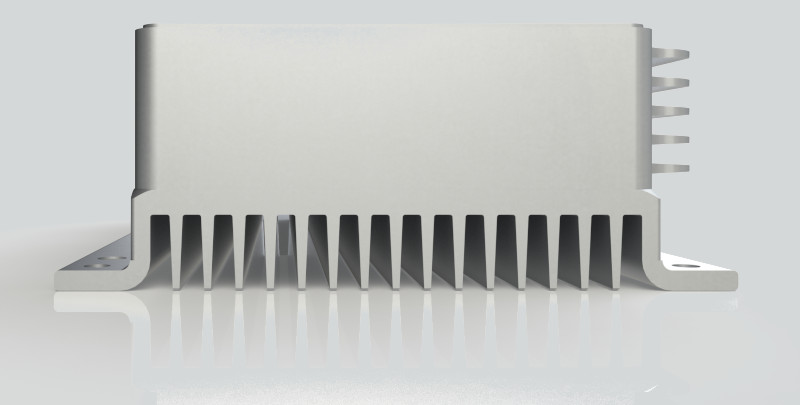

There are many rules to be observed when realising extruded profiles. The adjacent illustration shows that the limits of what is technically feasible are quickly reached. For an extruded profile of a high-voltage control unit, an extruded profile had to be produced, which is very difficult to manufacture. The large accumulation of material in combination with the fine fins presented our supplier with a challenge.

|

|  |

|

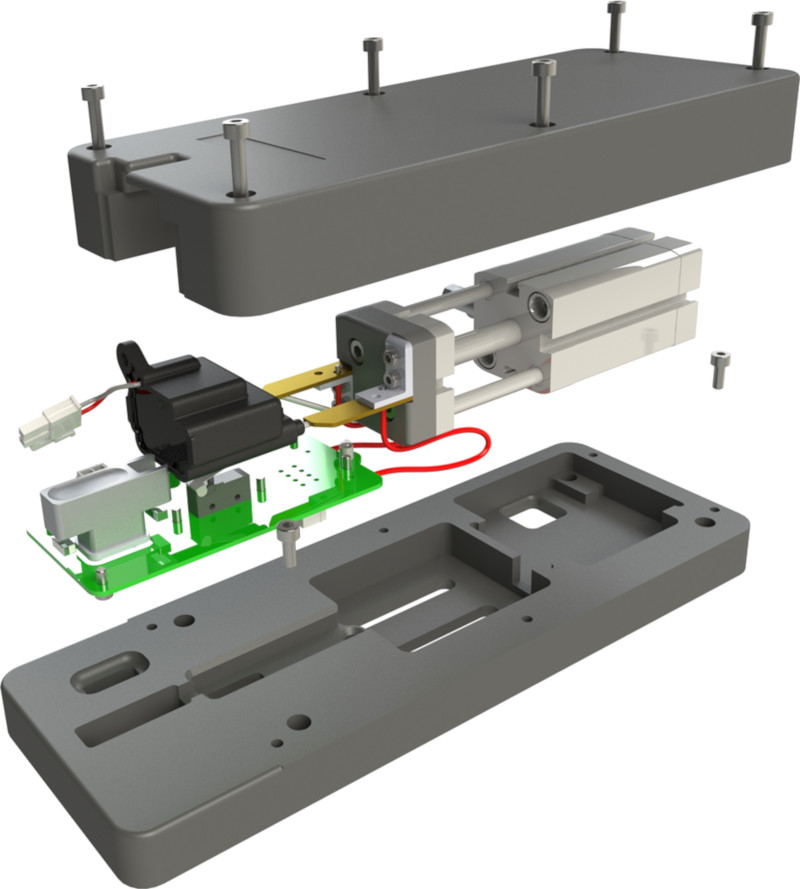

On the move...

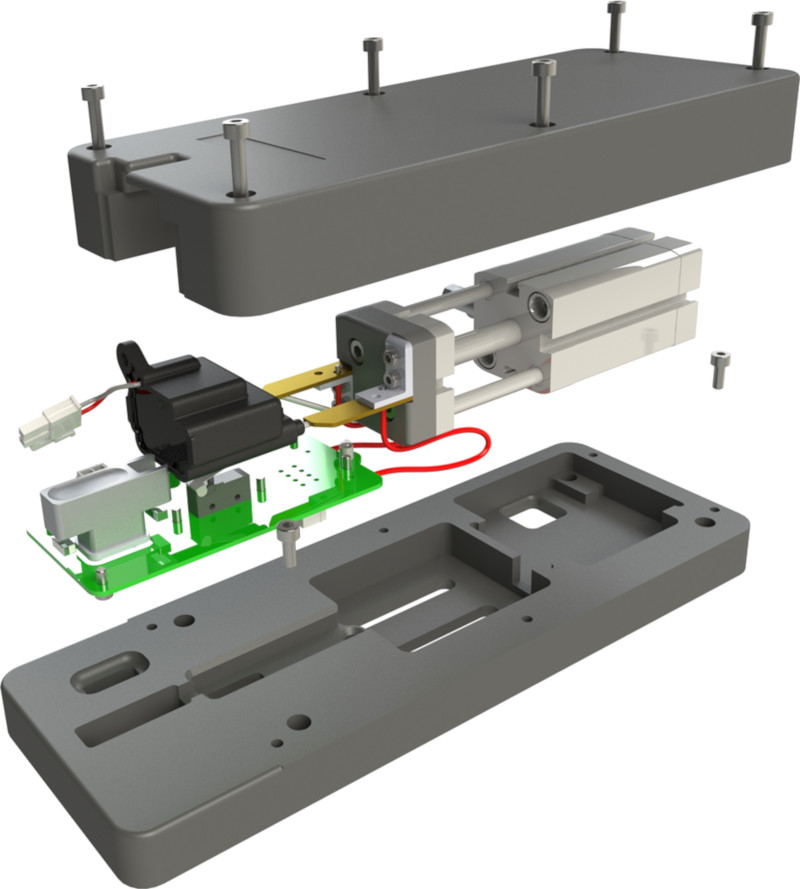

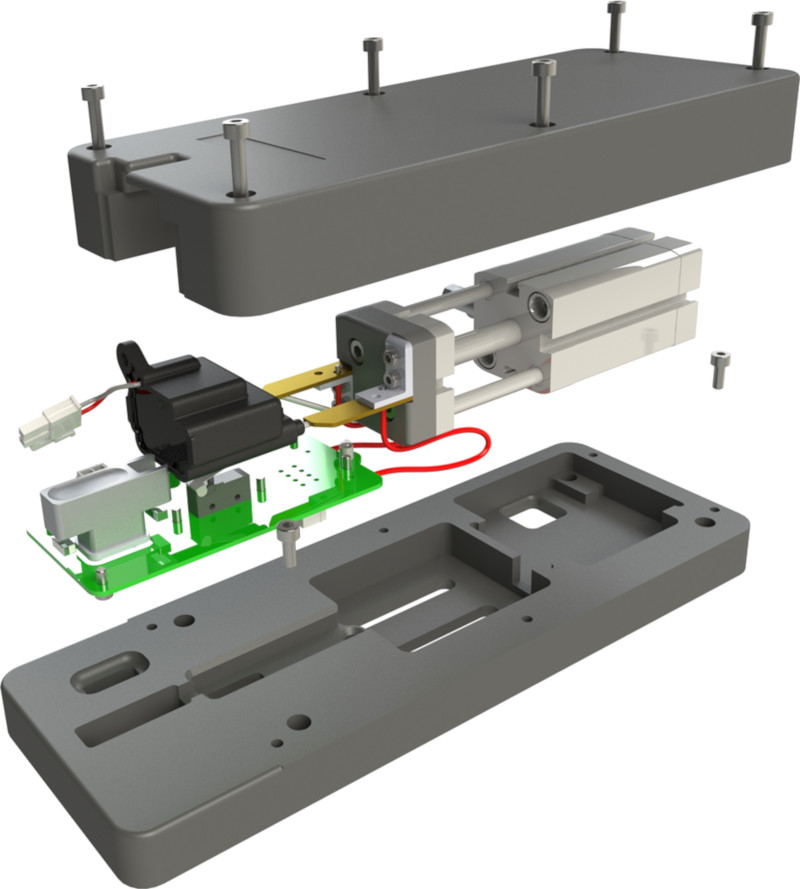

We develop special testing devices for our serial products. They are semi-automated to a large extent, meaning that contacting by pneumatic cylinders, for example, happens automatically. To protect the user and the test specimen, safety mechanisms are always integrated. For example, actuated microswitches have to send a release signal before a powerful pneumatic signal is activated.

An important feature of our testing devices is their robustness. For just under 15 years, some of them have been used every week without showing signs of mechanical wear.

|

|

|

|

|

Copyright © 2025 Exotronic GmbH. All rights reserved.

info@exotronic.de | +49 (0) 39605 279 0 | Schwarzer Weg 2 | 17094 Groß Nemerow | Germany

Data protection

Imprint

|

|

Range of services

• Constructing detailed components

• Visualising existing components

• Developing appealing picture masks for graphic interfaces

• Creating injection-moulded casing

• Creating extruded profiles

• Generating bent metal pieces

• Deriving technical drawings

• Creating photo-realistic images (rendering)

• Conversion into all common universal formats

|

|

We can do more...

As an example of the fact that we don’t just design electronic components, we have designed a bus and a motor vehicle for the website. The vehicles have their own exterior design, interior, tinted windows and photo-realistic surfaces.

A complex component in CAD but only a small detail on the homepage.

|

|

Extruded profiles

There are many rules to be observed when realising extruded profiles. The adjacent illustration shows that the limits of what is technically feasible are quickly reached. For an extruded profile of a high-voltage control unit, an extruded profile had to be produced, which is very difficult to manufacture. The large accumulation of material in combination with the fine fins presented our supplier with a challenge.

|

|

On the move...

We develop special testing devices for our serial products. They are semi-automated to a large extent, meaning that contacting by pneumatic cylinders, for example, happens automatically. To protect the user and the test specimen, safety mechanisms are always integrated. For example, actuated microswitches have to send a release signal before a powerful pneumatic signal is activated.

An important feature of our testing devices is their robustness. For just under 15 years, some of them have been used every week without showing signs of mechanical wear.

|

|

Copyright © 2025 Exotronic GmbH. All rights reserved.

info@exotronic.de | +49 (0) 39605 279 0 | Schwarzer Weg 2 | 17094 Groß Nemerow | Germany

Data protection

Imprint

|

Deutsch

Deutsch